United States

United States🔥 Reduced FedEx Shipping for CORE One! 🚀

Choosing a 3D printer: Which one should you get?

Choosing the right 3D printer can feel overwhelming, but it doesn’t have to be. To make things easier, start by asking yourself these simple questions:

What will I print most often?

Start by identifying the types of projects you’ll print most often. Whether it’s functional parts, decorative pieces, toys, or prototypes, knowing your main focus will guide your decision.

If we were to blindly suggest one of our 3D printers, we would go with the Prusa CORE One+, as it’s a good all-around choice.

How much space do I have for a 3D printer?

Before buying a 3D printer, consider the space available in your home, office, or workshop. Compact printers like the MINI+ are perfect for tight spaces or desktops, while large machines like the Prusa XL require more room but offer increased build volumes.

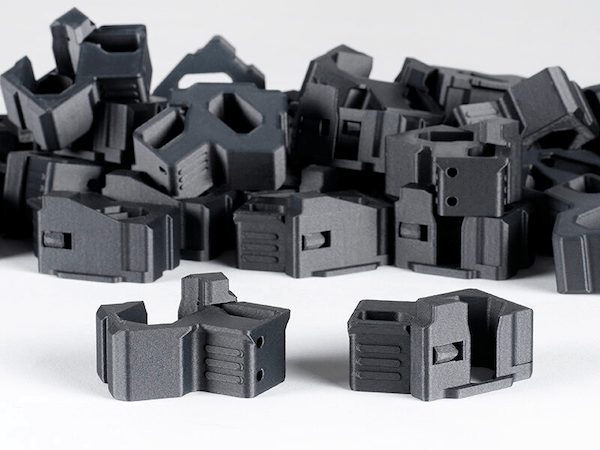

That said, bigger isn’t always better. Most projects can be printed on a medium-sized printer like the CORE One+, which strikes a great balance between footprint and capability. Even large models can often be split into smaller parts and assembled after printing. This approach saves space and resources while maintaining flexibility.

Will I work with advanced materials like ABS, ASA, Polycarbonate, Nylon?

If you’re planning to use advanced materials that require high temperatures and controlled environments, you’ll want a closed-frame printer like the CORE One+ or an enclosed XL. These materials provide enhanced mechanical, chemical, or UV resistance.

However, if you’ll primarily work with PLA and PETG, the two most commonly used materials, you can achieve excellent results with open-frame printers like the MK4S or the budget-friendly MINI+.

Do I need multi-material or color prints right away, or can I upgrade later?

Starting with a simpler single-material printer lets you get comfortable with 3D printing before upgrading. Many manufacturers, including Prusa, offer upgrade options. For example:

- The MMU3 add-on allows the CORE One+ and MK4S to print with multiple colors or materials.

- The XL supports additional toolheads for advanced multi-material printing.

This approach saves you money upfront while keeping future options open.

Does Print Speed Matter?

Print speed is a factor, but most modern 3D printers are fairly comparable in this regard. Don’t be lured by flashy specs like “20,000 mm/s² acceleration” without context. Raw numbers can sound impressive but don’t always translate to faster real-world prints.

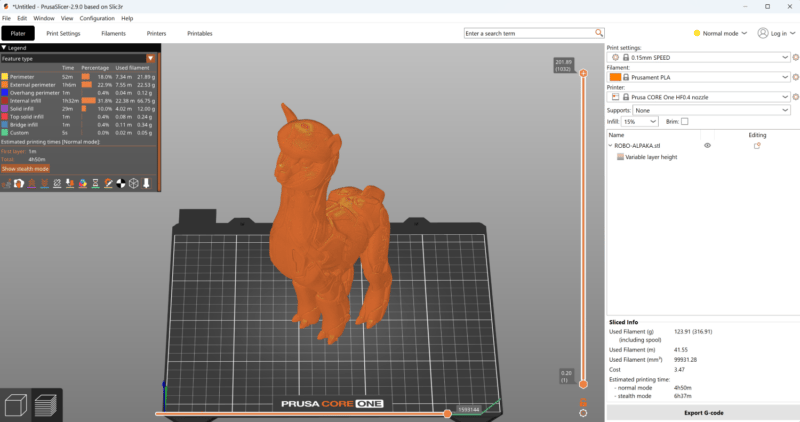

If you really want to compare speeds, look for print time comparisons of the same model, or download the manufacturers’ slicer software and test the same model with identical settings on different printers to see the true differences. For most users, reliability and consistent quality matter more than speed. After all, redoing failed prints due to rushed settings wastes far more time than a slower, successful run.

How much time and effort can I spend setting up?

If you want the “plug-and-print” experience right out of the box, choose the assembled version.

Building your own printer from a kit version is like putting together an advanced LEGO set. It’s cheaper than buying an assembled one, and you’ll understand your machine inside and out, which will make upgrades and maintenance easier down the road. It will take you two afternoon sessions to build our MK4S from an assembly kit.

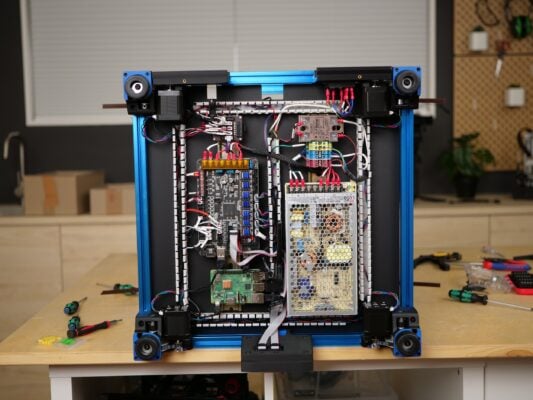

For those who are looking for a truly hands-on experience, open-source projects like Voron stand out. These printers are very DIY-focused and cater to enthusiasts who enjoy assembling and fine-tuning every aspect of their machine. While they require significant time and effort to build and optimize, the process can be rewarding and the friendly community will help you out with almost any problem you might encounter.

Budget and Long-Term Value

Prusa printers, proudly made in the EU, are designed to be reliable, have exceptional print quality, and be supported for years after their release. They receive regular firmware updates, the hardware can be upgraded over time, they are easy to maintain, making them an investment that grows with your skills and needs. With a thriving user community, Prusa printers are perfect for users who value long-term reliability and support.

If you’re just starting and are on a very tight budget, printers from overseas manufacturers can be an affordable way to explore 3D printing. Of course, you get what you pay for, and these printers come with their own drawbacks and shorter lifespans. But they can be a great entry point for newcomers and we are excited for anyone who starts their 3D printing journey.

Security

When it comes to 3D printers, security is often an overlooked aspect, but it’s an essential consideration, especially as printers become increasingly connected to local networks and the internet.

For professional environments, it’s almost unthinkable to connect a printer running unverified firmware to a secure network. Printers running open-source firmware allow for independent auditing, so companies and individuals can verify the absence of vulnerabilities or backdoors.

Some printers require cloud-based systems, while others allow you to work entirely offline, which is crucial for keeping proprietary designs confidential.

Quality of Life Features

Look for things like power-loss recovery (so your print resumes after a power outage), filament runout sensors (no more partial prints if the spool finishes mid-job), and remote monitoring (send files to your printer from your phone or PC, watch progress via a camera). These are small conveniences that can save big headaches.

What About SLA?

Resin printing, also known as SLA, uses liquid resin and UV light to create incredibly detailed models. SLA printers like the Original Prusa SL1S offer incredible detail, making them great for intricate jewelry designs or miniatures. However, SLA resin is more complex to handle, and each print requires washing and curing. It’s usually better for first-time users to start with an FFF printer and switch to SLA if your projects need ultra-fine details.